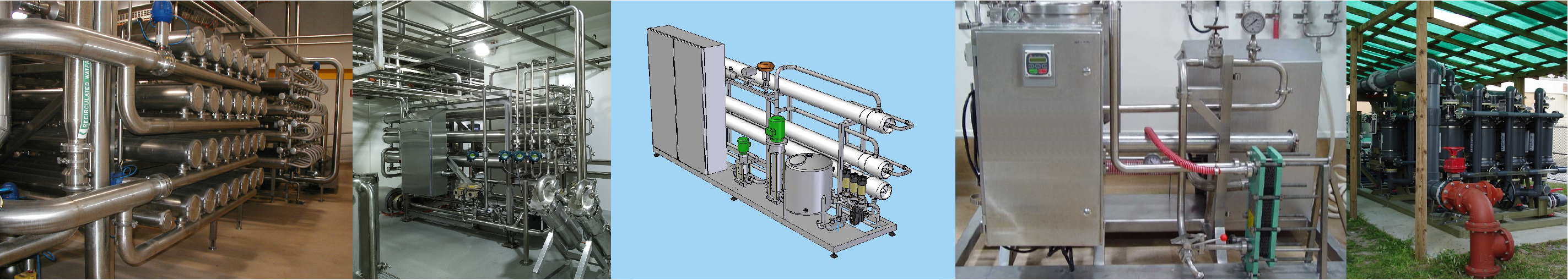

Membrane Systems

Membrane processing is our number one activity. With 50 plants processing over 20 million litres per day of various feed streams, we like to think we can help with most applications.

Our membrane plants are designed in-house, so we have the skills to troubleshoot or advise on plant expansions right here. No need to wait for responses from Europe or USA.

Basically, whenever there is a need to purify streams or separate components (such as fats, bacteria, proteins, sugars, salt and water) membrane processing could be the answer. Recovery and re-use of water and chemicals are great membrane opportunities.

We can offer complete custom design or skid/containerised plants for food and water applications.

Typical activities include:

Membrane Plants

Ultrafiltration

Nanofiltration

Reverse Osmosis

Microfiltration

Pilot Plants

Examples

Engineering

Plant Expansion

Troubleshooting

Automation Retro-fit

Replacement Membranes

Plant upgrades

Training

Contact us to discuss your particular application

Examples - Membrane Projects

Listed below is a selection of membrane plants that EPI has designed and manufactured.

PLANT TYPE |

CAPACITY |

APPLICATION |

|---|---|---|

| NF | 75,000 l/hr | Sweet whey concentration and Ash reduction. Includes diafiltration. |

| RO | 60,000 l/hr | Clean-up NF permeate suitable for re-use. |

| RO | 60,000 l/hr x3 | Clean-up evaporator condensate for re-use. |

| NF (special) | 20,000 l/day | Clean-up evaporator caustic for re-use. |

| UF | 40,000 l/hr | MPC80 manufacture. Plant also capable of variable flowrate and manufacture of MPC40 to MPC70. |

| NF | 50,000 l/hr | Acid Casein whey concentration and demineralisation. |

| NF | 60,000 l/hr | Caseinate whey concentration and demineralisation. |

| UF | 20,000 l/hr | Acid whey NF permeate processed to WPC35-50. |

| UF | 7,000 l/hr | Whey protein isolate (WPI90) concentration and demineralisation. |

| MF | 15,000 l/hr | Clean up and microbial reduction of mozzarella and gouda brine. |

| NF | 60,000 l/day | Demineralisation and solids recovery from cheeseroom salty whey. |

| RO | 50,000 l/hr | Concentration of milk UF permeate. |

| RO | 30,000 l/hr | Whey concentration. |

| UF | 10,000 l/hr | Milk concentration to increase protein and calcium levels. |

| UF | 50,000 l/hr | Milk concentration. |

| NF | 10,000 l/hr | Milk concentration to increase protein and calcium levels. |

| RO | 40,000 l/hr | Skim concentration for evaporator feed. |

| UF | 50,000 l/hr | Manufacture WPC35 from sweet whey. |

| NF | 40,000 l/hr | Concentrate and demineralise sweet whey UF permeate. |

| RO/NF/UF/MF | Pilot Plant | Multipurpose plant for trial purposes. |

| Various | N/A | Expansion, improvement, automation etc of other supplier’s plants such as APV, Koch, Niro. |